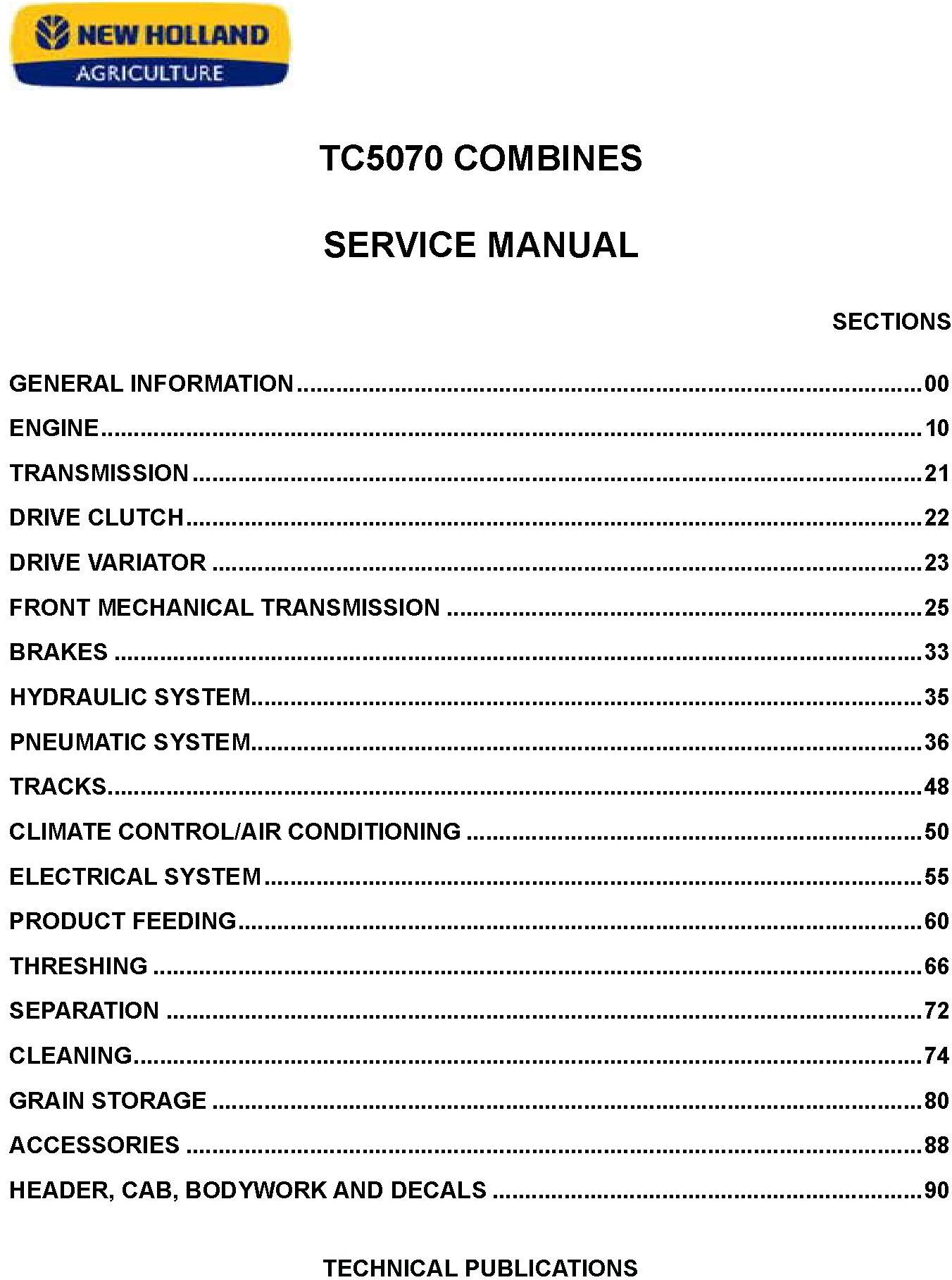

CONTENTS

This manual contains high quality images, diagrams, instructions to help you to operate, maintenance, diagnostic, and repair your truck. This document is printable, without restrictions, contains searchable text and bookmarks for easy navigation.

Language: English

Format: PDF, 708 pages

Covered models:

TC5070

Contents: Section 00 - GENERAL INFORMATION

Chapter 1 - Introduction

INTRODUCTION

COMBINE CARE

SAFETY NORMS

SPECIAL CARE

PRODUCT IDENTIFICATION

CONVERSION TABLE

TORQUE CHART

Chapter 2 - Drives and Controls

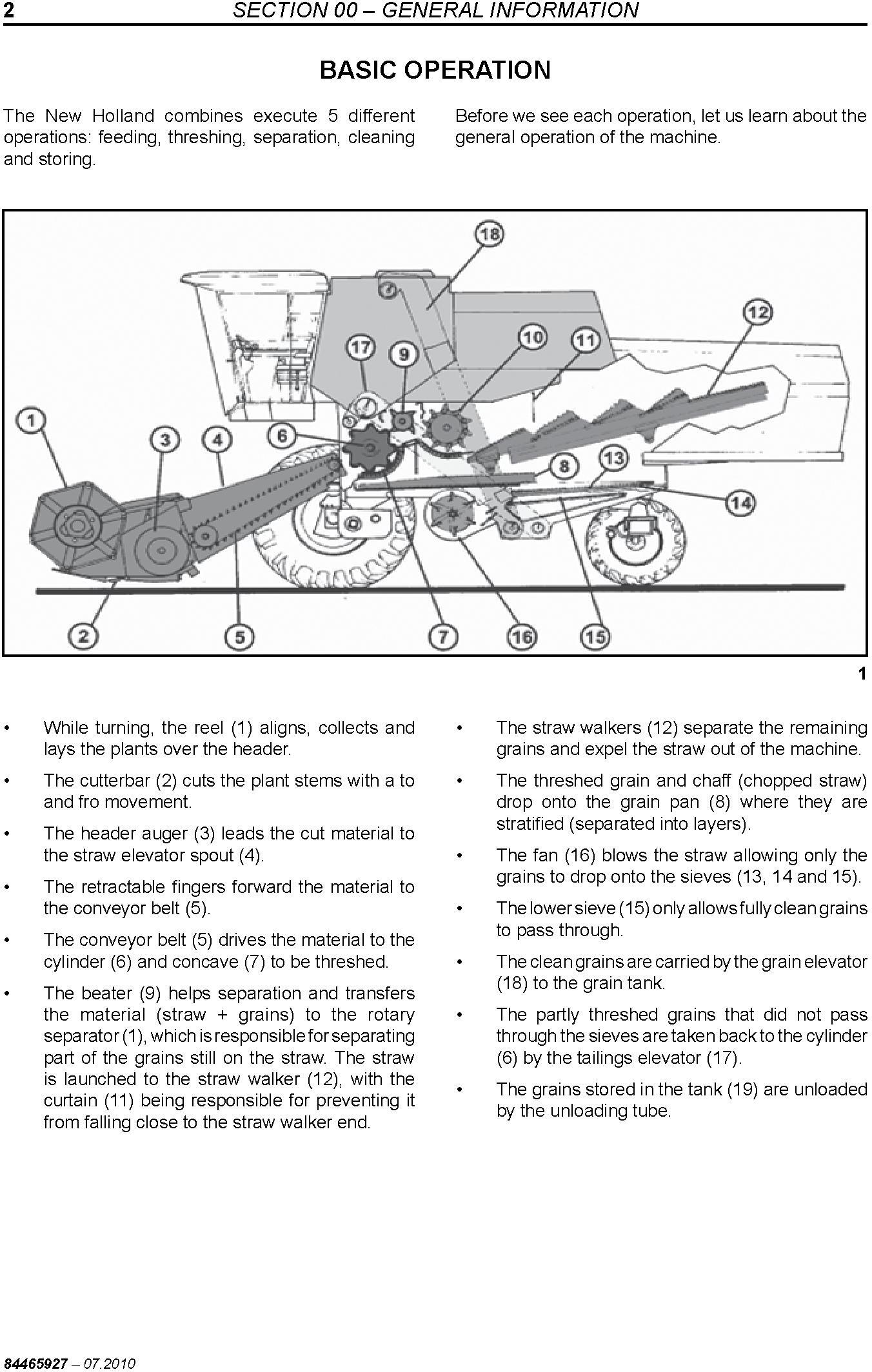

BASIC OPERATION

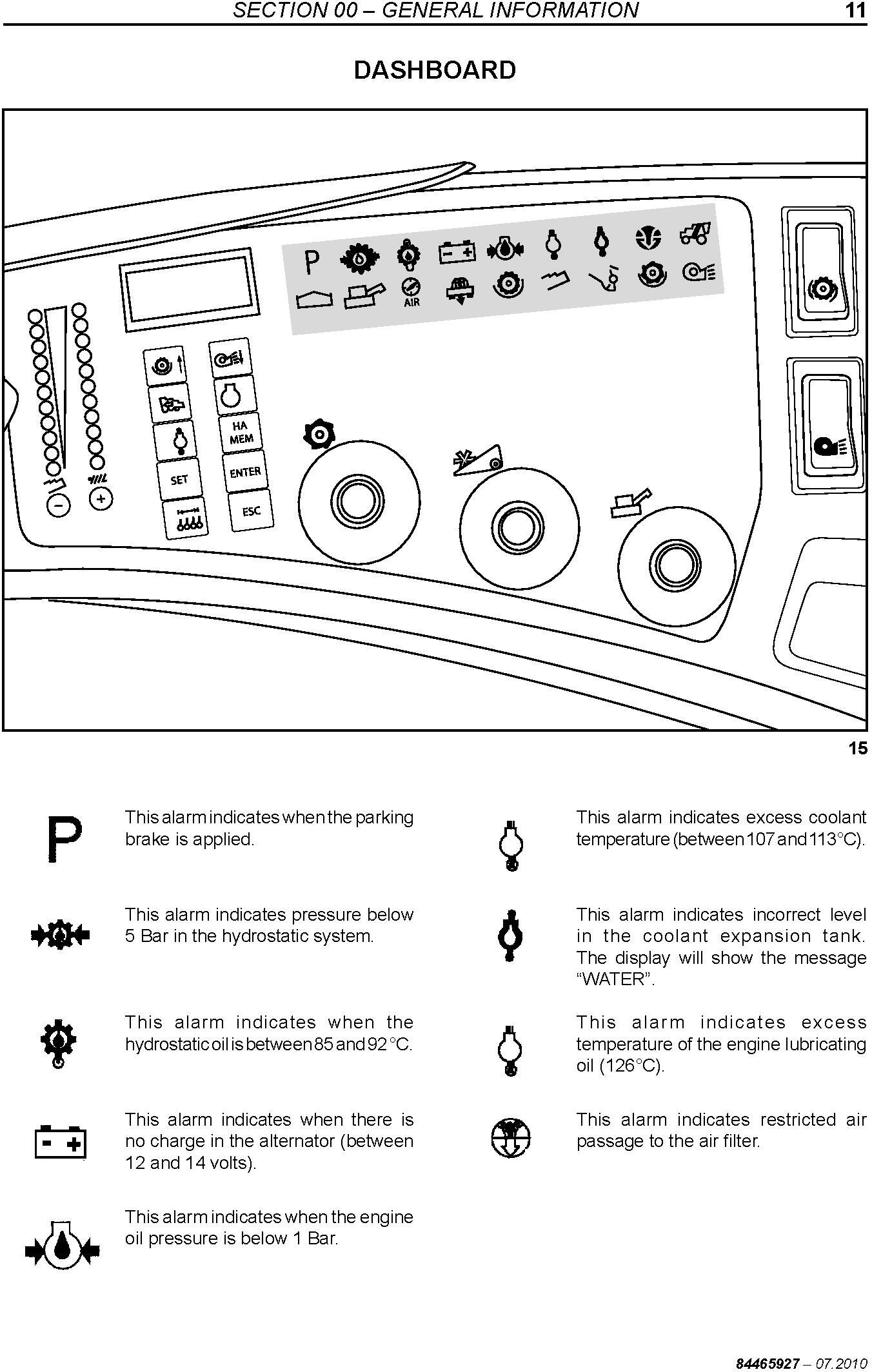

DASHBOARD

LOSS CONTROL (A)

General Module (B)

CALIBRATION KEYS

DISPLAY PROGRAMMING

DASHBOARD

DRIVE KEYS [hydrostatic transmission]

CONTROLS [hydrostatic transmission]

Multifunction Lever

DRIVE KEYS [mechanical transmission]

CONTROLS [mechanical transmission]

Chapter 3 - Maintenance

Lubricant specifications

MAINTENANCE AND LUBRICATION SCHEMATICS

ADJUSTMENTS AND MAINTENANCE

DRIVE BELTS AND CHAINS [right-hand side]

STEERING AXLE

AIR CONDITIONER

Chapter 4 - Field Adjustment

Safety Precautions for Operating on Hills

COMBINE ADJUSTMENTS

MEASURING GRAIN LOSS

LOSSES FROM THE MACHINE

troubleshooting

Section 10 - ENGINE

SPECIFICATIONS

ASSEMBLY DIMENSIONS

TIGHTENING TORQUES

Special tools

Engine Cold Starting

Cooling System

Lubrication System

Fault diagnosis

Installing the engine on the trestle

ENGINE DISASSEMBLY

Assembling the engine

checking and measuring

Valve clearance adjustment

ROTARY injection pump removal, installation and synchronization

Section 21 - TRANSMISSION

Gearbox 3MD

GEARBOX - TC5070 MECHANICAL

GEARBOX - TC5070 HYDRO

SPECIFICATIONS

Disassembly Sequence

Coupling and Inversion Carcass

Differential

Assembly Sequence

Section 22 - Drive clutch

DRIVE CLUTCH [mechanical transmission]

REAR WHEEL TOE-IN

Section 23 - Drive variator

Belt Tension Adjustment

Variator Adjustment

Variator Alignment

Section 25 - FRONT MECHANICAL TRANSMISSION

Chapter 1 - Standard Final Drive

STANDARD REDUCER ratio 10/75

WHEEL BOLT - REPLACEMENT

FINAL DRIVE - Removal/Installation

FINAL DRIVE - Disassembly/Assembly

Chapter 2 - Rice Final Drive

Specifications

Rice Drive Ratio 10/75

Section 33 - BRAKES

Chapter 1 - Brake Pad Replacement

BRAKE PAD REPLACEMENT

Chapter 2 - Brakes

BRAKES

Section 35 - hydraulic system

Chapter 1 - Basics

specifications

HYDRAULIC SCHEMATICS - TC5070 Mechanical

HYDRAULIC SCHEMATICS - TC5070 Hydro

HYDRAULIC SYSTEM

HYDRAULIC CONTROL - FULL SET

HYDRAULIC CYLINDERS

HYDROPNEUMATIC COMPENSATORS AND CYLINDERS

Chapter 2 - Hydraulic Motors

REVERSER HYDRAULIC MOTOR REMOVAL, INSTALLATION, DISASSEMBLY, INSPECTION AND ASSEMBLY

Practical maintenance tips for the HYDRAULIC MOTOR - PARKER

Chapter 3 - Steering

SPECIAL TOOLS

SPECIFICATIONS

STEERING VALVE

PUMP GROUP

Chapter 4 - Hydrosatic System

GENERAL PRINCIPALS

HYDROSTATIC TRANSMISSION

HYDROSTATIC SYSTEM (TC5070 Hydrostatic transmission)

Hydrostatic System mechanical adjsutments

HYDROSTATIC CIRCUIT AND COMPONENTS

MULTIFUNCTION VALVE

Disassembling and assembling the main components

Troubleshooting and measurement points

Chapter 5 - Auxiliary Drive I (4WD)

HYDROSTATIC CIRCUIT - AUXILIARY DRIVE

MAINTENANCE PROCEDURES

SHAFTS/GASKETS AND BEARINGS

Block and piston set

DISTRIBUTOR (VALVE BLOCK) AND DISTRIBUTION GASKETS

ACCUMULATOR

Chapter 6 - Auxiliary Drive II (4WD)

WHEEL MOTOR MAINTENANCE

Preventive Maintenance and Precautions

General Recommendations

TROUBLESHOOTING

Wheel Motors

WHEEL MOTOR OPERATION

General Information

Description

DISASSEMBLY AND ASSEMBLY OF THE REAR AXLE

Disassembly

Assembly

REAR AXLE MAINTENANCE

Basic maintenance requirements

Every 100 hours of Machine Operation:

Cross-section

Every 100 hours of Machine Operation:

STARTING PROCEDURE

TEST GAUGE LOCATIONS

Test Procedure Nº 2

Test Procedure Nº 3

TESTING PROCEDURE

Test Procedure Nº 1

Test Pressures versus Mode of Machine Operation

Troubleshooting

Fluidrive Rear Drive Systems

GENERAL INFORMATION

Safety Measures

Operation of the Fluidrive System

Chapter 7 - Troubleshooting

Troubleshooting the Hydraulic Circuit

Section 36 - Pneumatic System

Chapter 1 - Pneumatic System

SYMBOLS USED

HYDRAULIC CONTROL ROD ACTUATOR CYLINDER

MICRO SOLENOID VALVE 3/2 PORTS - NC (Normally Closed)

PNEUMATIC COMPONENTS

PNEUMATIC EQUIPMENT

PRESSURE REGULATOR

PNEUMATIC SYSTEM

PNEUMATIC SCHEMATIC

Chapter 2 - Pneumatic components

Pneumatic clutch

Section 48 ‒ TRACKS

Specifications

Assembly Torques

TRACKS

MAINTENANCE

TRACK INSTALLATION

TOWING INSTRUCTIONS FOR HARVESTERS EQUIPPED WITH TRACKS

Section 50 ‒ CLIMATE CONTROL/AIR CONDITIONER

Chapter 1 - A/C SYSTEM

Introduction

AIR CONDITIONING CIRCUIT

A/C CYCLE

COOLANT

TESTING AND TROUBLESHOOTING, GENERAL

PRELIMINARY TROUBLESHOOTING AND TESTING

PRELIMINARY DIAGNOSTICS CHART

TEST PROCEDURE ‒ STABILIZING THE SYSTEM TEST PORTS

A/C SYSTEM PERFORMANCE TEST AND DIAGNOSTICS CHART

GAUGE READINGS AND INTERPRETATIONS

Chapter 2 - CONDENSER

Description

Chapter 3 - FILTER DRIER

Description

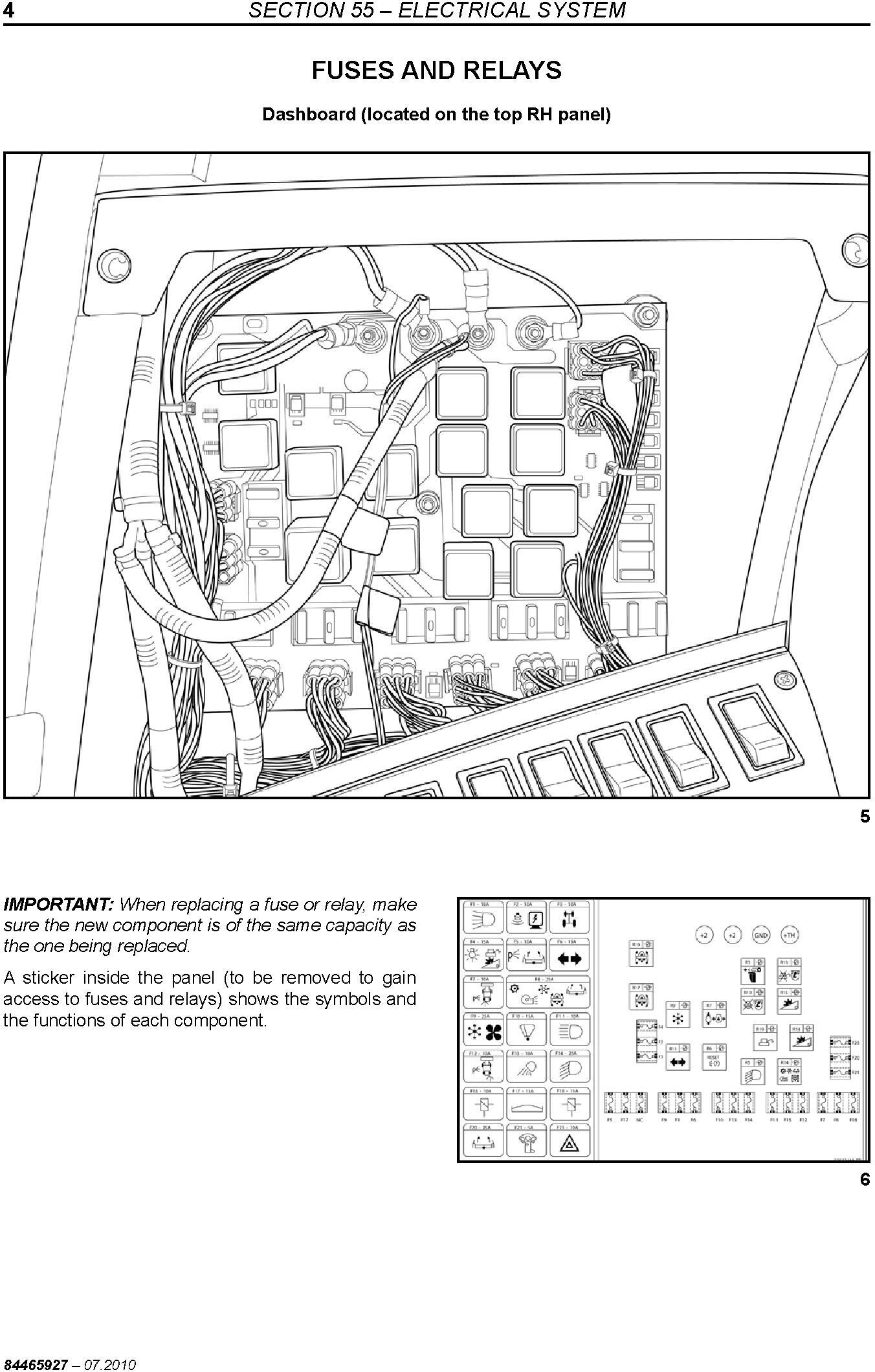

Section 55 ‒ ELECTRICAL SYSTEM

Chapter 1 ‒ Specifications

SPECIFICATIONS

Chapter 2 ‒ Component Identification

SWITCHES

Fuses and relays

SUMMARY OF ALARMS

ALERT CONDITIONS

Chapter 4 ‒ Troubleshooting Diagram

TROUBLESHOOTING

Chapter 5 ‒ Electric Schematics

ELECTRICAL SYMBOLOGY

ELECTRICAL SCHEMATICS

Section 60 ‒ PRODUCT FEEDING

Straw Elevator

Stone Trap

STRAW ELEVATOR TRACK CHAINS

UPPER SHAFT

Check the dimensional

Section 66 ‒ THRESHING

Chapter 1 ‒ Cylinder and concave

THRESHING CYLINDER

CONCAVES

TEETH CONCAVE OPENING (RICE)

Section 72 ‒ Separation

Chapter 1 ‒ Beater

BEATER

Chapter 2 ‒ Rotary Separator

Rotary Separator

Chapter 3 ‒ Straw Walker

Straw Walker

Chapter 4 ‒ Grain pan

GRAIN PAN

Section 74 - CLEANING

Fan

CANVAS AIR DEFLECTOR

Replacement of the fan belts

VARIATOR ADJUSTMENT DEVICE

Fan Case

SIEVES

FITTING THE GRAIN PAN DIVIDERS

Section 80 ‒ GRAIN STORAGE

Grain and tailings auger

Leveling Auger and Tailings

Unloading tube auger

Section 88 ‒ ACCESSORIES

Chapter 1 ‒ Straw Chopper

STRAW CHOPPER

TROUBLESHOOTING

Section 90 ‒ HEADER, CAB, BODYWORK AND DECALS

Chapter 1 ‒ Coupling grain header and corn spout

CUTTING PLATFORM

C.A.A.P. Adjustment/F.3L.

BLADES AND BLADE BOX

REEL

FEED AUGER

Chapter 2 ‒ Cutter bar drive box

Disassembly

TROUBLESHOOTING

ADJUSTMENTS FOR THE CORN HARVEST

FIELD WORK

ADJUSTMENTS AND MAINTENANCE

LUBRICATING NIPPLES

Grease Nipples

Transmission Boxes

Chains

Chain maintenance after the harvest

SERVICE SCHEDULE

LUBRICATION

ROW UNIT SAFETY CLUTCH (TORQUE LIMITER)

DISASSEMBLY OF THE GEARBOX AND ROW UNIT SAFETY CLUTCH

Gearbox

Removal of the gearbox

Stalk rolls ‒ Synchronism of the pullers

Gearbox disassembly

Disassembly and assembly of the safety clutch

Reinstallation of the divider points and dividers

Retaining bracket

Ear saver

ROW UNIT TRANSMISSION BOX

ARTICULATED DIVIDER POINTS

Articulated Points

Drag Plates

Angle of Inclination of Row Units

Vertical Inclination of the Row Units

Row Unit Attachments

Row Unit Drive

SETTING THE DISTANCE BETWEEN ROWS

SETTING THE ROW UNITS

ROW UNIT GUARDS

REVERSER SYSTEM

DECK PLATES

LEFT SHIELD AND DEFLECTOR

ELECTRICAL CONTROL OF THE DECK PLATES

Corn Header Activation

Corn Header Height Control [mechanical transmission]

Corn Header Height Control [hydrostatic transmission]

Adjusting the Distance Between the Deck Plates

FEEDER AUGER AND ROW UNIT DRIVE

Feeder auger with total helix in the center

Feeder auger height

Adjustment of the safety clutch

FEEDER CHAINS

Stalk rolls

Replacement of the stalk rolls

Adjustment of the weed knives and the stalk rolls

Adjustments of the weed knives (Counter knives)

Stalk roll adjustment

PNEUMATIC SYSTEM

SIEVE

FAN

STONE TRAP

CONCAVE

STRAW ELEVATOR ADJUSTMENTS

Straw elevator chain tension

Adjustment of the front axle suspension spring

Chain

STRAW ELEVATOR ‒ HEADER COUPLING

Support Shoes

Coupling the corn header to the combine

HEADER SIZES

REQUIRED PROCEDURES FOR CORN

SPECIFICATIONS

INTRODUCTION

COMBINE CARE

END-OF-SEASON SERVICE

MAINTENANCE BETWEEN SEASONS

SERVICING BEFORE THE SEASON.

SAFETY NORMS

TOWING THE HARVESTER

TRANSPORTING THE MACHINE

Stopping the machine

Adjusting the machine

SPECIAL CARE

PRODUCT IDENTIFICATION

CONVERSION TABLE

TORQUE CHART

BASIC OPERATION

DASHBOARD

LOSS CONTROL (A)

General Module (B)

Instruments:

CALIBRATION KEYS

DISPLAY PROGRAMMING

DASHBOARD

DRIVE KEYS [hydrostatic transmission]

Function of switches

Complementary Switches and Controls

CONTROLS [hydrostatic transmission]

Multifunction Lever

DRIVE KEYS [mechanical transmission]

Function of switches

CONTROLS [mechanical transmission]

Safety Precautions for Operating on Hills

COMBINE ADJUSTMENTS

MEASURING GRAIN LOSS

Simplified Procedure

Specific Measurement Procedure

LOSSES FROM THE MACHINE

troubleshooting

Gearbox 3MD

GEARBOX ‒ TC5070 MECHANICAL

GEARBOX ‒ TC5070 HYDRO

SPECIFICATIONS

Technical data and adjustment values

Temperature for Assembly

Tightening Torques

Disassembly Sequence

Coupling and Inversion Carcass

Idler Shaft

Drive Shaft

Differential Cover

Differential

Differential

Gearbox Carcass

Assembly Sequence

Differential

Gearbox Carcass

Differential Cover

Drive Shaft

Idler Shaft

Reverse Shaft

Cover Adjustment

Fork assembly

Fork Setting

Adjusting the Variator Shaft Bearing Axial Clearance

Adjusting the idler shaft bearing axial clearance

Shift Cover

DRIVE CLUTCH [mechanical transmission]

Bleeding the clutch hydraulic command

REAR WHEEL TOE-IN

Rear axle pivot positions

Belt Tension Adjustment

Variator Adjustment

Variator Alignment

Specifications

Rice Drive Ratio 10/75

Disassembly

Assembly

BRAKE PAD REPLACEMENT

Removal

Installation

Brake shoe disasembly and assembly

BRAKES

SERVICE BRAKE ADJUSTMENT

PARKING BRAKE ADJUSTMENT

BLEEDING THE CONNECTION BETWEEN THE TWO MAIN CYLINDERS

BLEEDING THE RIGHT-HAND CIRCUIT

REVERSER HYDRAULIC MOTOR REMOVAL, INSTALLATION, DISASSEMBLY, INSPECTION AND ASSEMBLY

Preliminary Preparation for Disassembly

Removal and Installation

Disassembly and Inspection

Assembly

Final check

Rotor assembly

Practical maintenance tips for the HYDRAULIC MOTOR ‒ PARKER

SPECIAL TOOLS

SPECIFICATIONS

STEERING VALVE

Characteristics

Removal

Installation

Disassembly

Assembly

PUMP GROUP

Main hydraulic pump

Hydraulic pump (steering circuit)

Hydraulic pump (side floating circuit)

HYDROSTATIC CIRCUIT - AUXILIARY DRIVE

How it Works

MAINTENANCE PROCEDURES

Wheel - motor cut view

Wheel - motor component

SHAFTS/GASKETS AND BEARINGS

Disassembly

Assembly

Block and piston set

Disassembly

Assembly

DISTRIBUTOR (VALVE BLOCK) AND DISTRIBUTION GASKETS

Disassembly

Assembly

ACCUMULATOR

Description and operation

Disassembling the accumulator

Information to replace the accumulator

Installing the accumulator

GENERAL PRINCIPALS

Circuit

Description and operation of the variable yield pump

Description and operation of the hydrostatic motor

Operation of the fixed displacement motor

Rotating direction

HYDROSTATIC TRANSMISSION

Hydrostatic pump (cut view)

Hydrostatic motor (cut view)

HYDROSTATIC SYSTEM (TC5070 Hydrostatic transmission)

Technical Data

Hydrostatic system oil change and refilling

Hydrostatic System mechanical adjsutments

Adjust the control cable

Belt tension adjustment

HYDROSTATIC CIRCUIT AND COMPONENTS

MULTIFUNCTION VALVE

Disassembling and assembling the main components

Troubleshooting and measurement points

Hydrostatic pump

CHARGE PUMP

Disassembly

Assembly

Hydrostatic motor

GENERAL INFORMATION

Safety Measures

Operation of the Fluidrive System

Troubleshooting

Fluidrive Rear Drive Systems

TESTING PROCEDURE

Test Procedure Nº 1

Test Pressures versus Mode of Machine Operation

TEST GAUGE LOCATIONS

Test Procedure Nº 2

Test Procedure Nº 3

STARTING PROCEDURE

REAR AXLE MAINTENANCE

Basic maintenance requirements

DISASSEMBLY AND ASSEMBLY OF THE REAR AXLE

Disassembly

Assembly

WHEEL MOTOR OPERATION

General Information

TROUBLESHOOTING

Wheel Motors

WHEEL MOTOR MAINTENANCE

Preventive Maintenance and Precautions

Troubleshooting the Hydraulic Circuit

Steering

Header

Reel

Unloading Tube

Drive Variator

Lateral Flotation

Reverser

Others

SYMBOLS USED

HYDRAULIC CONTROL ROD ACTUATOR CYLINDER

Installation of the sintered filter

MICRO SOLENOID VALVE 3/2 PORTS - NC (Normally Closed)

PNEUMATIC COMPONENTS

Solenoid Valve

Rotary Joint

Drier Filter

Pneumatic Cylinder

Reverser Pneumatic Cylinder

Ball Valve

PNEUMATIC EQUIPMENT

Selector Valve ("OR" Element)

Ball Valve

Reverser Control Valve

PRESSURE REGULATOR

Schematic

Lubricator

PNEUMATIC SYSTEM

PNEUMATIC SCHEMATIC

Pneumatic clutch

Removing the pneumatic clutch

Disassembling the pneumatic clutch

Assembling the pneumatic clutch

Disassembling the pneumatic clutch

Assembling the pneumatic clutch

Specifications

Assembly Torques

TRACKS

New Holland Tracks for Rice Harvesters

Introduction

Front Axle

Rolling material

Straw elevator

Drive Wheels

Shoes

Attaching to the Harvester

Rear Tires

MAINTENANCE

TRACK INSTALLATION

TOWING INSTRUCTIONS FOR HARVESTERS EQUIPPED WITH TRACKS

Introduction

Correct use of the air-conditioning system

Storage maintenance

AIR CONDITIONING CIRCUIT

Location of the A/C components

A/C CYCLE

Air-conditioning process

Lubricants

Operation

COOLANT

Refrigerant recovery procedure

Washing

Recharge/Refilling

Use of a manifold gauge set

Checking refrigerant for excess air

Containers for the storage of recycled refrigerant

Transfer of refrigerant

Disposal of empty or near empty disposable containers

Applicable SAE standards

Related SAE standards

TESTING AND TROUBLESHOOTING, GENERAL

General safety and service precautions

Check for leaks

Cleanliness

Refilling

Contaminants

Prevent mixing of service equipment

PRELIMINARY TROUBLESHOOTING AND TESTING

Operational checks ‒ Heating

Operational checks ‒ A/C

PRELIMINARY DIAGNOSTICS CHART

TEST PROCEDURE ‒ STABILIZING THE SYSTEM TEST PORTS

A/C SYSTEM PERFORMANCE TEST AND DIAGNOSTICS CHART

GAUGE READINGS AND INTERPRETATIONS

Description

Removal

Installation

Description

Troubleshooting

Removal

Installation

SPECIFICATIONS

SWITCHES

Fuses and relays

SUMMARY OF ALARMS

ALERT CONDITIONS

Cylinder VARIATOR BELT ‒ Removal/Installation

THRESHING CYLINDER VARIATOR DRIVEN DISKS ‒ Removal/Installation

Threshing cylinder variator drive disks ‒ Removal/Installation

CYLINDER VARIATOR ADJUSTMENT

BEATER

Specifications

Replacement of the shaft and the bearings

Rotary Separator

Speed adjustments

Procedure to replace the Rotary Separator

Straw Walker

Fitting the crests

Position of the crests

Disassembly of the straw walker and shafts

Assembly of the straw walker shafts

Care during shaft installation

Straw walker bearings

GRAIN PAN

Characteristics

Disassembly and assembly of the grain pan and the stone trap

Fan

CANVAS AIR DEFLECTOR

Replacement of the fan belts

VARIATOR ADJUSTMENT DEVICE

Fan Case

Disassembly

Assembly

SIEVES

Types of sieve available

Factory sieve adjustment

Removing the sieves

Installation

Installation of the Upper Sieve with Self-Leveling System

FITTING THE GRAIN PAN DIVIDERS

Grain and tailings auger

Disassembly

Assembly

Leveling Auger and Tailings

Tensioning of the grain/tailings elevator conveyor chains

Disassembly of the leveling auger

Assembly

Disassembly of the tailings auger

Assembly of the tailings auger

Unloading tube auger

Disassembly of the unloading tube and auger

Installation of the unloading tube and auger

Adjustment of the unloading auger bearing

STRAW CHOPPER

SPECIFICATIONS

OPERATION

Deflector

Straw guide vanes

BELT TENSION ADJUSTMENT

Front belt

STRAW CHOPPER SPEED ADJUSTMENT

DEFLECTOR PLATE

TROUBLESHOOTING

CUTTING PLATFORM

Specifications

Cutting platform coupling to the harvester

Uncoupling the cutting platform

Horizontal leveling of the platform

Cutting platform

C.A.A.P. Adjustment/F.3L.

CAAP Adjustment

Lateral Flotation Adjustment

BLADES AND BLADE BOX

Maintenance of the blade drive box

Knife Replacement

Cutter Bar Alignment

Blade Adjustment

REEL

Leveling

Vertical adjustment

Hydraulic Horizontal Adjustment

Positioning of fingers

Tensioning the drive chain

FEED AUGER

Drive

Specifications

Flotation adjustment of the auger/retracting fingers

Disassembly

Assembly

SPECIFICATIONS

HEADER SIZES

STRAW ELEVATOR ‒ HEADER COUPLING

Support Shoes

STRAW ELEVATOR ADJUSTMENTS

CONCAVE

STONE TRAP

FAN

SIEVE

PNEUMATIC SYSTEM

FEEDER CHAINS

Stalk rolls

Replacement of the stalk rolls

Adjustment of the weed knives and the stalk rolls

FEEDER AUGER AND ROW UNIT DRIVE

Feeder auger with total helix in the center

Feeder auger height

Adjustment of the safety clutch

ELECTRICAL CONTROL OF THE DECK PLATES

Corn Header Activation

Corn Header Height Control [mechanical transmission]

Corn Header Height Control [hydrostatic transmission]

Adjusting the Distance Between the Deck Plates

REVERSER SYSTEM

DECK PLATES

LEFT SHIELD AND DEFLECTOR

SETTING THE DISTANCE BETWEEN ROWS

ARTICULATED DIVIDER POINTS

ROW UNIT TRANSMISSION BOX

ROW UNIT SAFETY CLUTCH (TORQUE LIMITER)

DISASSEMBLY OF THE GEARBOX AND ROW UNIT SAFETY CLUTCH

LUBRICATION

SERVICE SCHEDULE

LUBRICATING NIPPLES

Grease Nipples

Transmission Boxes

Chains

ADJUSTMENTS AND MAINTENANCE

FIELD WORK

ADJUSTMENTS FOR THE CORN HARVEST

TROUBLESHOOTING